Six Sigma Risk Management Strategies leverage process mapping to visualize and optimize business workflows, identifying bottlenecks and potential risks. By applying DMAIC principles, organizations can systematically analyze data, uncover inefficiencies, and implement targeted improvements for enhanced operational stability and customer satisfaction. Process maps, integral to this approach, offer detailed insights into complex processes, enabling informed decision-making and proactive risk mitigation.

Process mapping is a powerful visual tool for identifying and managing risks within business operations. This article explores how organizations can leverage process mapping and Six Sigma risk management strategies to make data-driven decisions. We’ll guide you through understanding process maps, mapping out critical business processes, uncovering key risk metrics, and implementing effective mitigation plans. By the end, you’ll be equipped with actionable insights for enhancing overall risk management using these proven Six Sigma techniques.

- Understanding Process Mapping: A Visual Approach to Risk Identification

- The Role of Six Sigma in Risk Management: Strategies for Data-Driven Decisions

- Mapping Out Your Business Processes: Steps to Create an Effective Flowchart

- Uncovering Risk Metrics: What to Look For and How to Measure It

- Implementing Risk Mitigation Strategies: Using Process Maps for Actionable Insights

Understanding Process Mapping: A Visual Approach to Risk Identification

Process mapping is a powerful visual tool that simplifies complex business processes, making it an essential technique in Six Sigma risk management strategies. By creating detailed diagrams, organizations can gain insights into how different components interact and identify potential risks or bottlenecks. This method allows for a holistic view of operations, enabling teams to make informed decisions and develop effective mitigation plans.

Through process mapping, businesses can visually trace every step, decision point, and outcome within a specific workflow. This visual representation helps in recognizing areas prone to errors, delays, or quality issues. By analyzing these maps, Six Sigma experts can pinpoint critical risk metrics, set targets for improvement, and design tailored strategies to enhance overall process efficiency and resilience.

The Role of Six Sigma in Risk Management: Strategies for Data-Driven Decisions

Six Sigma, renowned for its data-driven approach to process improvement, plays a pivotal role in modern risk management strategies. By applying Six Sigma principles, organizations can systematically identify, quantify, and mitigate potential risks, ensuring decision-making processes are grounded in robust data analysis. This methodical approach involves defining, measuring, analyzing, improving, and controlling (DMAIC) various aspects of business operations, including risk factors.

In the context of risk management, Six Sigma encourages a culture of continuous improvement. It equips professionals with tools to gather and interpret relevant data, enabling them to make informed decisions. By employing statistical techniques and process mapping, organizations can uncover hidden risks and inefficiencies, leading to better strategic planning and enhanced overall performance.

Mapping Out Your Business Processes: Steps to Create an Effective Flowchart

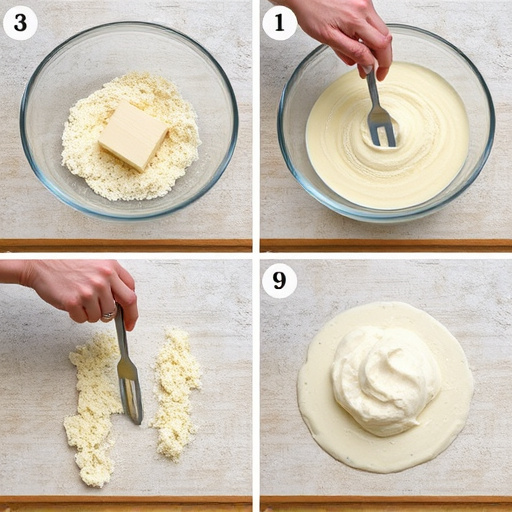

Mapping out your business processes is a crucial step in identifying risk metrics using Six Sigma Risk Management Strategies. Start by defining the scope and objectives of your process map, ensuring it aligns with your overall goals for risk assessment. Break down complex activities into simpler tasks and organize them in a logical sequence, often starting from the initial trigger to the final outcome. This involves creating a flowchart that visually represents each step, its inputs, outputs, and decision points.

Utilize standard symbols like rectangles for processes, diamonds for decisions, and arrows to show the flow of work. Involve key stakeholders who can provide detailed insights into their respective roles and potential pain points. As you construct the chart, pay attention to bottlenecks, delays, or areas prone to human error, as these are common risk indicators. Regularly review and update your process map to reflect changes in operations, ensuring it remains an accurate representation of your business workflow.

Uncovering Risk Metrics: What to Look For and How to Measure It

Uncovering risk metrics is a critical step in effective Six Sigma Risk Management Strategies. When mapping out processes, pay close attention to variability and inconsistencies that could indicate potential risks. Metrics such as defect rates, cycle times, and customer complaints are valuable indicators of process fragility. By quantifying these measures, you gain actionable insights into areas requiring improvement.

To measure risk effectively, establish clear thresholds and set up monitoring systems. Define what constitutes an acceptable level of risk for each metric and use data analytics to track trends over time. This proactive approach allows for the early detection of deviations, enabling you to implement Six Sigma strategies to mitigate risks before they escalate, ultimately enhancing process stability and customer satisfaction.

Implementing Risk Mitigation Strategies: Using Process Maps for Actionable Insights

Implementing effective risk mitigation strategies is a critical step in any Six Sigma Risk Management approach. Process maps, as a powerful visual tool, play a pivotal role in this process by offering actionable insights into potential risks and their underlying causes. By mapping out workflows and procedures, organizations can identify bottlenecks, weak links, and areas prone to errors or delays. This visual representation facilitates better understanding of complex processes, enabling teams to make informed decisions about risk mitigation.

With the help of process maps, Six Sigma methodologies provide a structured framework for analyzing and addressing risks. By plotting out each step in a process, it becomes easier to pinpoint where potential issues might arise. This allows for the development of tailored strategies to mitigate these risks, be it through process optimization, error prevention, or contingency planning. The actionable insights gained from process maps empower organizations to proactively manage risks, ensuring smoother operations and enhanced overall quality.

Process mapping is a powerful tool in the arsenal of Six Sigma risk management strategies. By visually representing business processes, organizations can uncover hidden risks and inefficiencies. This data-driven approach, through effective flowchart creation, allows for precise identification of risk metrics. Armed with this knowledge, companies can implement targeted mitigation strategies, ensuring a more robust and adaptable risk management framework. Embracing these methods enables businesses to stay ahead of potential challenges, fostering a culture of continuous improvement.